Technology has brought so much ease to mankind. The system of work has been revolutionized ever since the invention of technology. The nominal manual labor has become obsolete, the energy of manpower isn’t really imputed in the system of work.

These technological inventions help in the control, automation, and efficiency of processes in the industrial sector. Talking about the industrial sector, industries like the oil and gas industry isn’t excluded.

Due to the heavy-duty processes that are carried out in the oil and gas industry, the oil and gas industry is subdivided into three sectors. These sectors are responsible for all that is needed for the simplification of crude and distilling it into parts that are fit for human consumption.

These three sectors are the upstream, midstream, and downstream sector. We vividly explain each below

UPSTREAM SECTOR

The upstream sector of the oil industry, commonly called the exploration and production sector, involves the production end of the oil business. The upstream sector includes exploration for potential oil reserves, both onshore and offshore. Then subsequently, the drilling of these reserves with production rigs to bring oil and gas to the surface.

MIDSTREAM SECTOR

In the midstream sector, workers gather, process, refine, store, and transport the oil and gas produced by the upstream sector.

Midstream sector workers may also be involved in the wholesale marketing of crude oil and petroleum. They also work to apply technologies and equipment that increase the efficiency of these midstream processes, such as automated communications and pipe leak detectors.

DOWNSTREAM SECTOR

The downstream is the sector with which the average consumer is most familiar. This sector refines crude petroleum and oil and processes and purifies natural gas for consumer products.

Gasoline, asphalt, natural gas, jet fuel and much more are all products we use every day that come from the downstream sector.

Since we have established this fact about the oil and gas sectors, let’s see how instrumentation as a technological tool has benefited the oil and gas sector.

INDUSTRIAL INSTRUMENTATION

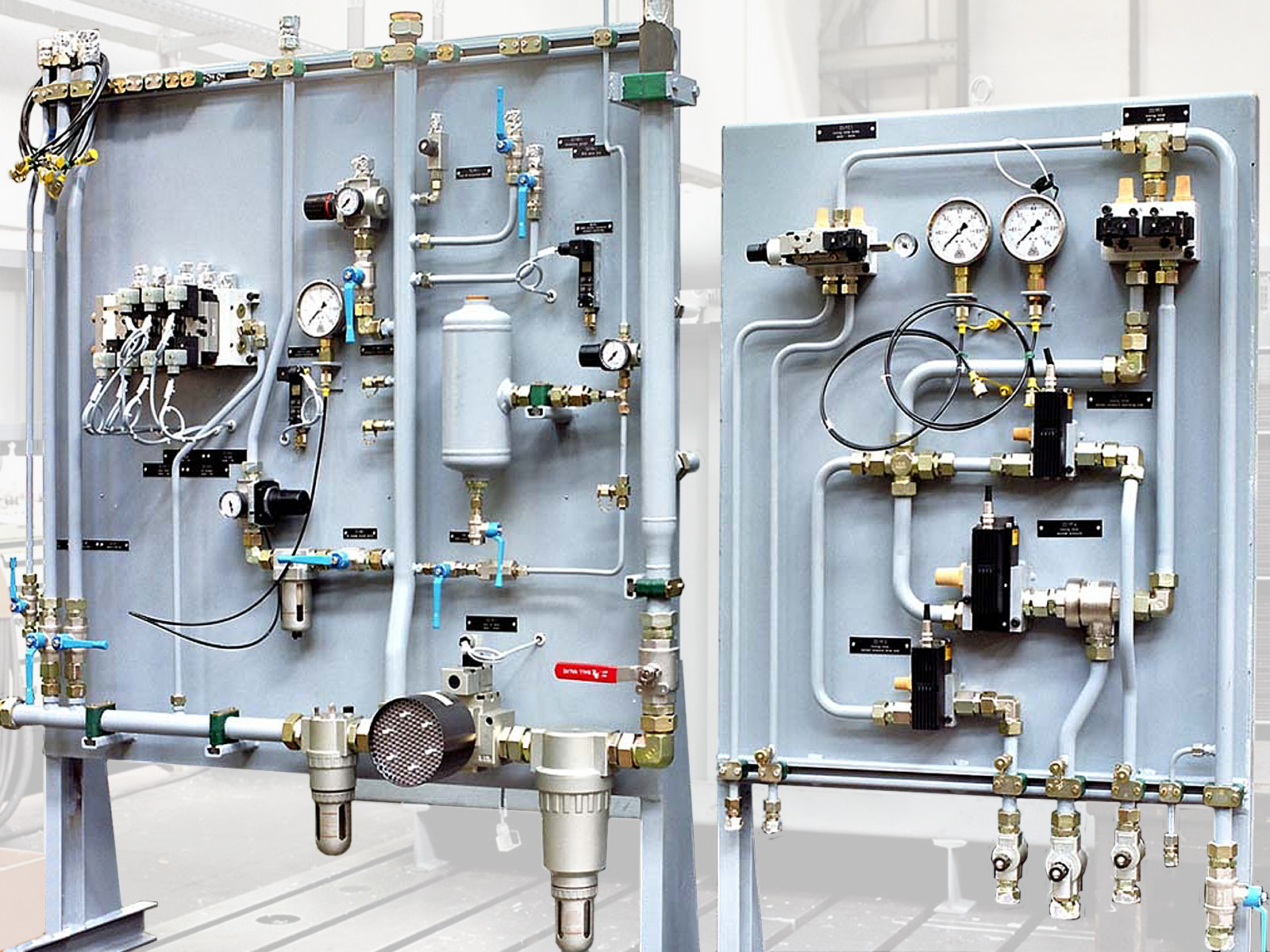

Industrial instrumentation is used to control and monitor conditions including temperature, pressure and fluid levels in processing facilities, oil refineries, petrochemical plant, oil and gas pipelines, and distribution operations.

Common applications of oil and gas instrumentation include monitoring the presence of flammable and combustible gases in production and storage areas and monitoring emissions for pollution control. Instrumentation is also used for monitoring and controlling flow in delivery systems.

According to petrochemical engineers, there are two types of instrumentation used in equipment monitoring: input and output.

Input instruments are used to monitor or measure temperature, flow, pressure, and levels in equipment including transport pipes and vessels.

Output instruments include controls and alarms that display readings or provide an alert to warn of potentially hazardous situations.

COMPONENTS OF INDUSTRIAL INSTRUMENTATION

The primary components of industrial instrumentation are sensors, transducers and transmitters.

- Sensors: In the oil and gas industry, sensors provide continuous measurement to detect and monitor gas. They also measure the physical properties of a solid, fluid or gas.

- Transducer: The transducers convert variation in temperature, pressure, flow or level into an electric signal.

- Transmitters: This serves as an interface between sensors and measurement instrumentation such as level sensors, flow meters, and pressure sensors. The transmitters are also responsible for sending a digital signal to the main control system.

IMPROVED SAFETY COMPLAINCE FOR OIL AND GAS INSTRUMENTATION

The oil and gas industries process a variety of hazardous substances that can cause explosions or catastrophic events and endanger the safety of humans and the environment.

Field instrumentation provides monitoring and control that is essential for ensuring compliance with safety and environmental regulations.

When integrated into automation systems, petrochemical processing equipment also helps manufacturers increase productivity and product consistency by delivering data regarding process efficiency and product quality.

Diopter technologies is an industry leader in control and monitoring equipment for oil and gas applications. We know how crucial reliable, high precision process instrumentation is for petroleum production, and we can help you find the right equipment for your specific application.

WHAT TO CONSIDER BEFORE CHOOSING ANY OIL AND GAS INSTRUMENTATION

It is important to consider the following criteria when researching options for oil and gas instrumentation:

- Operating conditions: The environmental conditions of your operating environment are a critical consideration in selecting processing instruments. Exposure to extreme heat and chemicals or other caustic substances can damage sensors or impact the reliability of the readings.

- Performance Characteristics: Different applications have different requirements for sensitivity, sensor reading range and accuracy, screen type and resolution, and general performance.

- Maintenance Requirements: Field instrumentation requires regular maintenance, including calibration, to ensure accuracy reliability. Choose instruments that are easy to maintain and are from a company that provides onsite maintenance services when required.

- Reliability & Durability: Processing instrumentation should be durable enough to withstand your operating conditions and frequency of use.

- Impact on Processes: Determine if and how the type of oil and gas instrumentation you select will impact flow control or equipment processes.

BENEFITS OF INSTRUMENTATION

If you have read through this article up to this point, it should give you a perspective on the benefits of instrumentation to the oil and gas industry.

However, assumption is the lowest level of knowledge. Let me quickly list out the benefits of instrumentation to the industry sector.

- It Reduces Labor Costs: The biggest benefits of the process control industry are automated efficiency. When you implement your process control instrumentation and rework your operations, you will see less of a need for your existing machine or human labor.

- It improves quality: These process control systems can be able to maintain the product quality. Using instrumentation and control systems maintain the proper ratio ingredients, regulate temperatures and monitor outputs.

- It helps in maintaining consistency: Using the proper instrumentation to remodel and rework your internal operations allows your machines to reduce variability and run to the best of their abilities.

It also helps employees ease physical labor, reduce energy, become more productive, and enhance daily work speed.

Just as technological solutions has transformed the industrial sector, Instrumentation is not doing less when it comes to the oil and gas industry. It has totally transformed the oil and gas sector.

The three sectors in the oil and gas industry are not excluded. It affected all the parts of the industry with the aim of increasing efficiency. Increased efficiency leads to cost reduction. Cost reduction leads to increase in revenue.

However, experts need to be aware of what to consider when choosing an instrumentation process. These considerations can save time and resources.

Lastly, the benefits of instrumentation are not what you should ignore. They serve as guides when considering installing an instrumentation system in your work process, especially if you are in the oil and gas industry.

CONCLUSION

Are you a decision maker, an industry expert, or a professional in the oil and gas industry?

Do you seek to increase the efficiency of distillation, or you desire to enhance the productivity of employees and team members?

Diopter technologies offers a variety of services in instrumentation. You can choose to leverage our industry knowledge and expertise in installing this system.

Or you can decide to enroll for our hands-on practical training, taught by experts with industry knowledge. These trainings are done both onsite and online.Take advantage of Diopter technologies today and enjoy the dividends tomorrow.