At the advent of modern machinery, the ease of work has been very profound. Industries who make use of thismodern machines have experienced enormous growth.

These machineries are utilized to ensure the effective operations in the different industries. The presence of these machineries has helped toin increaseing workplace productivity, reduces cost, and enhances the modality of work for companies who take advantage of them.

These A modern machineries employs some form of pneumatic component within its makeup and function.

Yet it can be argued that the majority of people know little about the industry and how components have evolved into being essential elements.

To understand how pneumatic components have become important parts of many inventions we use today, we need first to understand their history.

BRIEF HISTORY OF PNEUMATICS

Humans have recognised and used the technology behind pneumatics for thousands of years. The first discovery of a pneumatics-based device was in 429AD. is from blow guns in 429ADBlow guns; a tool that primitive hunters used to shoot their prey.

The ideas behind pneumatics were then first written down by a Greek mathematician Hero of Alexandria in the first century. He wrote and described how his inventions used the wind to generate power and move objects.

These inventions influenced German physicist Otto von Guericke to invent the vacuum pump in the 1600s. This pump could draw out air or gas by using air pressure.

In theDuring the Industrial Revolution, the inventions of Guernicke’s inventions brought about many other pneumatics inventions, especially for the transportation, communication, and manufacturing industries. For example, the compound air compressor whose purpose is to compress air in cylinders was first patented in 1892.

The effectiveness of the compressor improved drastically in 1872 by cooling the cylinders with water jets.

More functional uses of pneumatics started in 1867 with Alfred Beach who built a pneumatic subway train in New York; the first subway in the United States.

The subway used pneumatics to transport the vehicle through the underground tunnel, but it only lasted a few months after its construction in 1870. The perfection of electric multiple-unit traction and vehicles occurred shortly after this experiment, so an expanded pneumatic system was not deemed worthwhile.

Furthermore, John Wanamaker introduced pneumatic tubes to the United States Post Office in 1875 to transport letters throughout the building. Soon after, department stores implemented these tubes so that cashiers could transport money and important documents around the store.

IN THE 1900s

Since the invention boom of the 1800s, there has been a dramatic increase in the amount and usage of compressed air devices. After the 1960s, many of these pneumatic components were also digitally controlled.

Pneumatics are almost everywhere today, from the axial flow and centrifugal compressors in jet engines to the air tool that helps clean your teeth at a dentist’s office.

Most roller coasters also utilize pneumatics, the roller coaster with the fastest acceleration in the world is the only coaster in the world that uses a pneumatic air-launch system.

At this point, you may be wondering what pneumatics are. Take a chill pill, we’ did get down to that now.

WHAT IS PNEUMATICS?

Remember a time when you blew up a balloon, held it a moment, then let it zoom madly round the room?

What seemed like a great big, goofy old joke back then was really a basic lesson in pneumatics –putting pressurized air to practical use. From factory machines and road drills to paint spraying robots and power tools, all kinds of everyday things rely on pneumatics.

It sounds like a huge contradiction: how can something as useless and empty as air do such wonderfully useful things? How can you lift a helicopter, drill a hole, or power a train with just a big old bag of nothing? It’s all down to the simple science of pressure and the way gases store energy when you squash them up.

Let us get closer.

Pneumatics is a branch of mechanics that deals with the mechanical properties of gases. This field focuses on using pressurized gas also known as compressed air to produce mechanical motion and the application of such gases to produce motion.

The term pneumatic is used to describe a mechanical device that is powered by compressed air. Systems based on pneumatics rely on compressed air. The energy produced by pneumatic systems can be more flexible, less costly, more reliable, and less dangerous than that produced by devices powered other ways, such as with actuators or electric motors.

HOW DOES PNEUMATICS WORK?

Pneumatic machines need five basic components to make, store, control, move, and use compressed air:

- A compressor helps to make air.

- A reservoir helps to store air.

- One or more valves helps to control air.

- A circuit helps to move air between the other components.

- An actuator or motor uses air to do something different

Pneumatic devices get all their power from the energy in the compressed air they use, so you can probably see straight away that they need at least two key components: something to compress the air (the compressor) and something that uses compressed air to lift, move, or hold an object (the actuator).

We also need a pipe or network of pipes (the circuit) to get air from the compressor to the actuator. Something to switch the air on or off (a valve) and maybe to reverse its direction would also be handy (so we can make our machine lower things as well as lift them).

Compressors

The compressor is the machine that turns ordinary air into compressed air. It is the starting point for any pneumatic circuit, it is the bit that puts energy into the system by squeezing air into a much smaller space.

Now it is important to note that air isn’t like the fuel you load into a gasoline engine. It doesn’t contain much useful energy to begin with.

Squeezing energy into ordinary air is the job that the compressor does, although it doesn’t actually “make” this energy out of nothing.

Actuator

Actuator is an engineering jargon that just means mover, it is the business end of a pneumatic tool. the bit that shifts about and does some useful job for us.

It might be a pneumatic drill bit thumped up and down by a piston, a factory ramp that lifts things and lowers them, a mechanical arm that swings things around, or something like that.

Actuators typically move back and forth in a straight line (the technical word for that is reciprocate) and, as in the animation above, they’re often powered by pistons that slide back and forth in cylinders as compressed air flows in and out of them.

Circuits

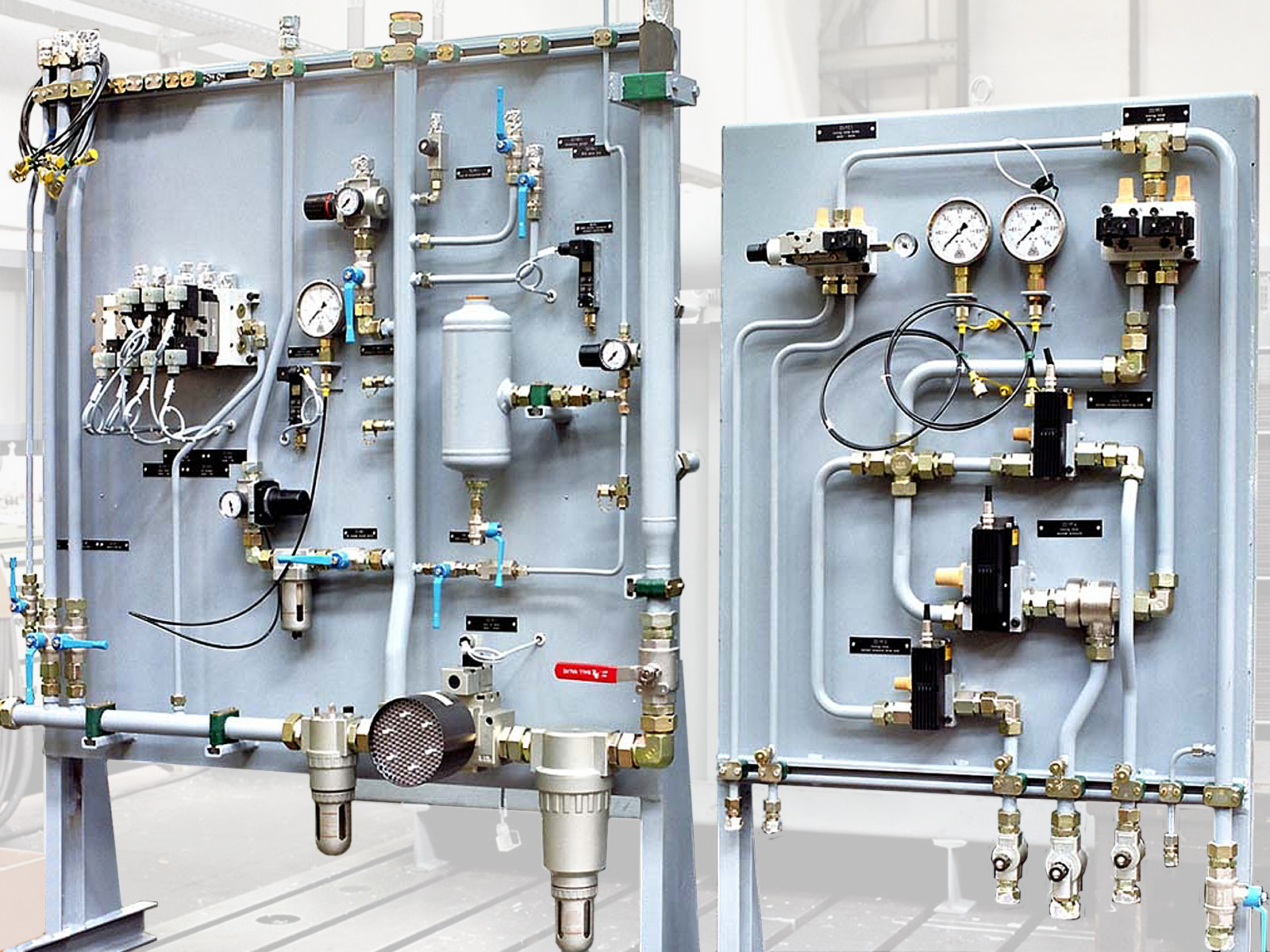

Although some pneumatic machines might have a single compressor, actuator, valve, and reservoir, most are more complex than this.

There are many kinds of actuators and valves, and a factory might have all kinds of machines driven from a complex circuit by a single, large compressor.

You can make complex electronic circuits from different arrangements of the same basic components, and you can make complex pneumatic circuits in exactly the same way.

There are dozens of little pneumatic symbols to help you draw circuits out clearly on engineering plans, just as there are symbols for electronic and hydraulic components.

Add Summary

In conclusion, you have seen how imperative pneumatics are to varied industries. The good news is, you too can learn how to utilize this pneumatic system in practical terms.

Diopter technologies is offering a hands-on practical training on pneumatics that is at par with industry demands.

We have experts with industry knowledge who will help you achieve your industry goals with this training. Get trained with Diopter technologies today.